Are you inadvertently being victimized by the added Chinese tariffs on your packaging imports from China because of your “Knowledge Gap”?

You might want to rethink the round of recent arbitrary price increases passed along by Chinese Export Agents / Import Agents and American Packaging Distributors because of the Chinese Trade War. Surprisingly, three things should be directly offsetting the impact of United States Tariffs including; market share preservations, export tax rebate manipulation, and currency fluctuation. All are key components to why you should not be taking price increases and Chinese manufacturers should be absorbing the tariffs through price reductions.

Chinese culture and business strategy are generally more long-term focused than their American counterparts—this especially applies to market share. Simply put, the fabric of Chinese culture is to view things from a long-term perspective. Relationships are often more important than short term profits; protecting market share for the long term is critical for Chinese Manufacturers. Letting the short-term tumultuous United States political environment inflict lasting damage on the Chinese manufacturing sector will not serve Chinese companies nor the Chinese Government’s future well. Your Export Agent or Packaging Distributor should be helping you leverage volume and the use of long-term agreements to gain price concessions given the current market uncertainty in China.

Additionally, the Chinese government has already increased subsidies to protect exports from China by offering rebates that discount the Chinese domestic VAT tax system for exports. This has been a long-standing government policy since the Chinese tax reforms in 1985 when the rebate was originally implemented broadly in China. On average these rebates amount averages 16%, but it depends on the commodity. For examples, in September of 2018, the Chinese Government increased rebates on plastics from 13% to 16% netting a 3% gain for Chinese exporters, a direct offset to the tariffs. This is a little known trigger to help Chinese companies compete in the world market and do it profitably. In November of 2018, the Chinese government announced that it will also speed up the time it takes to pay rebates, loosening constraints on cash flow for Chinese manufacturers that export. This is in addition to currency devaluation.

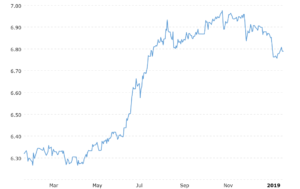

Perhaps the most obvious factor contributing to the rationale of beating the tariff tremor and impact of the Trade War is the manipulation of the Chinese Yuan. Already it accounts for a significant offset to the impact of the United States tariffs totaling $250 billion USD dollars per year. Since the beginning of 2018, the currency devaluation has already adjusted from 6.49 to 6.88% or a devaluation of 5.72%, which is a direct offset to the 10% increase leaving a real impact of 4.28% on products being procured from China. Yet many experienced Import Agents and Packaging Distributors continue to pass along 10% increases.

Image Source: macrotrends.com

How does this translate into beating the Chinese Tariff War Tremor? Using the relationships and knowledge of your Export Agent or Packaging Distributor to negotiate lower costs is a reasonable and achievable expectation to offset the United States tariffs. Having a transparent view of the variables that are affecting costs both on a Micro and Macro level fills the “Knowledge Gap” giving you negotiating power. This is critical for US customers to protect their bottom line instead of others in the supply chain padding theirs.

Proactively, you should be working closely with your Import Agent or Packaging Distributor to minimize cost increases. A little effort can yield tremendous results in minimizing or eliminating the new tariffs. If we simply adjust our pricing for the currency and export rebate changes, we can assume the real impact of the United States Chinese Trade War Tariffs is not 10% but 1.5%, hardly enough to justify Chinese manufacturers losing market share.

Authored by: George W. Dempsey Jr, CEO of Dempsey International Packaging

George is a leading expert on Asian and Latin American Packaging Supply Chain dynamics. His expertise spans 25 years of supply chain and business development in foreign markets, including multiple board level positions. He is a graduate of Northern Illinois School of Business and holds multiple degrees including an Executive MBA.